Patented PAN-FSP Nano-Fabrication

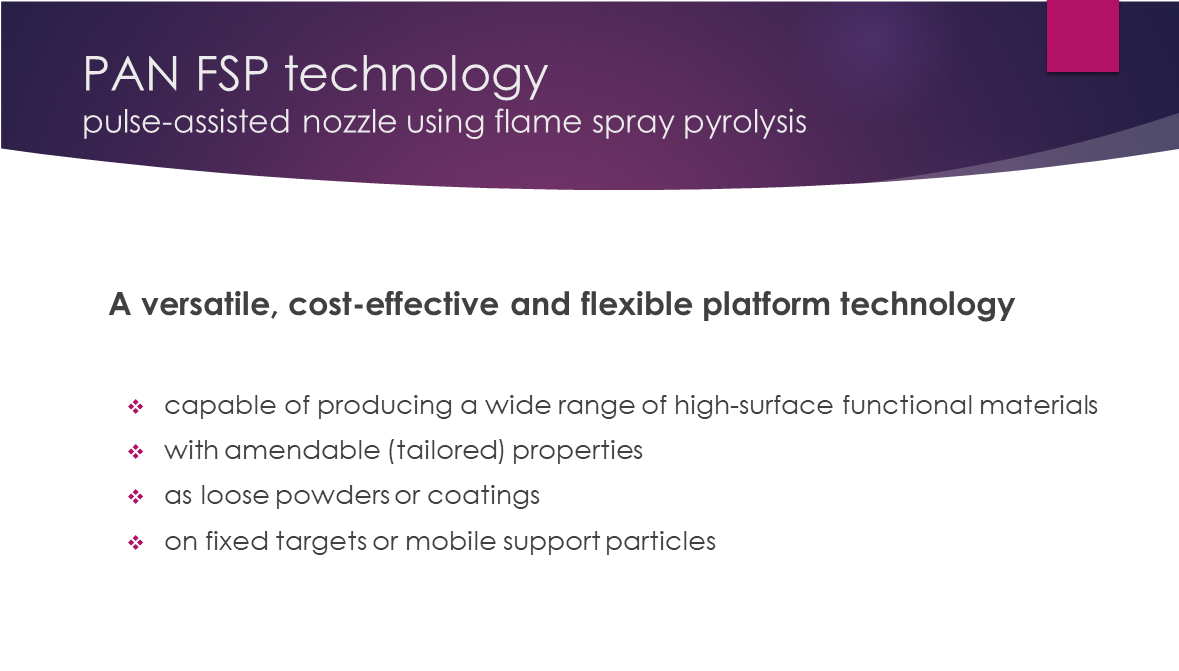

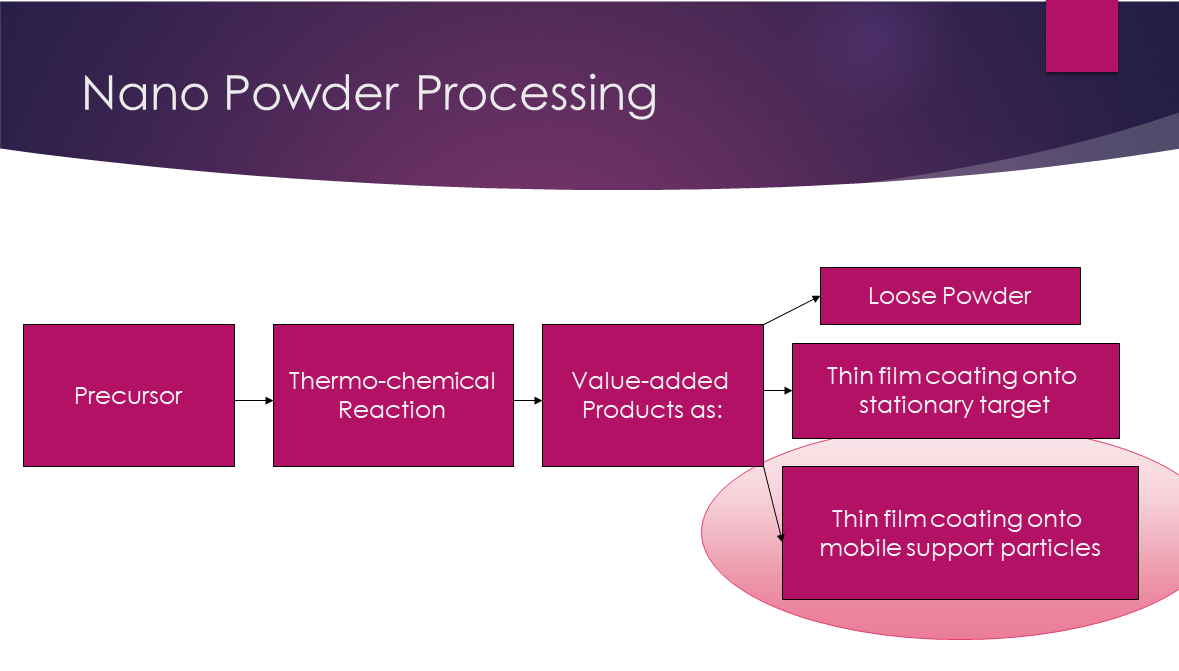

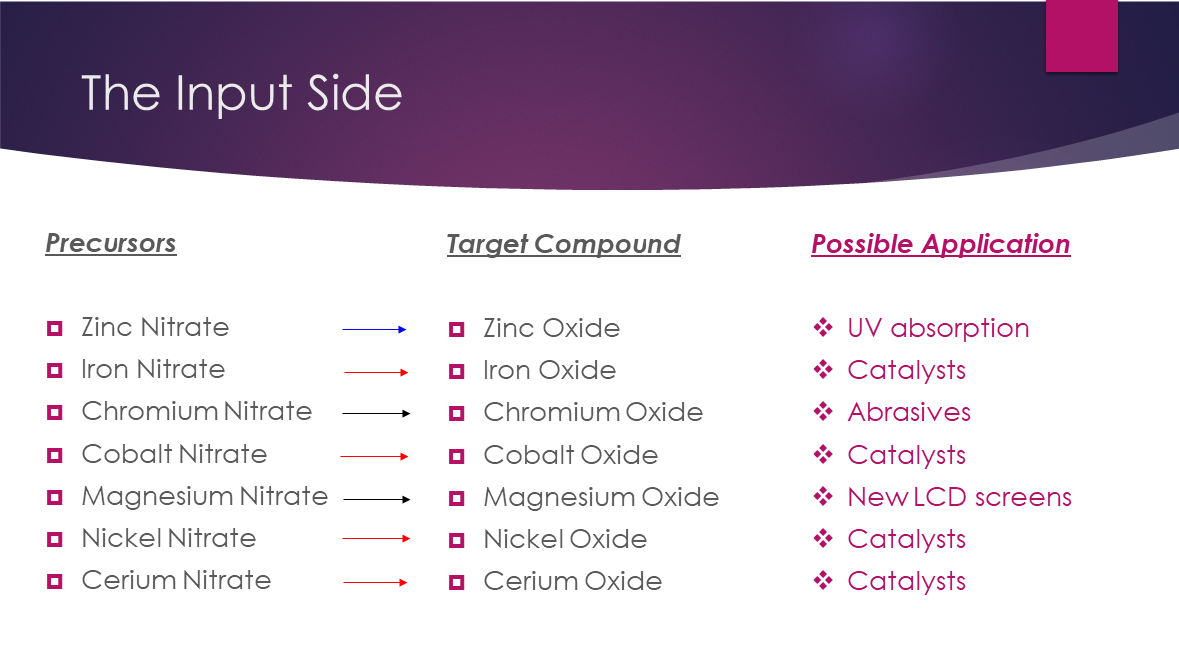

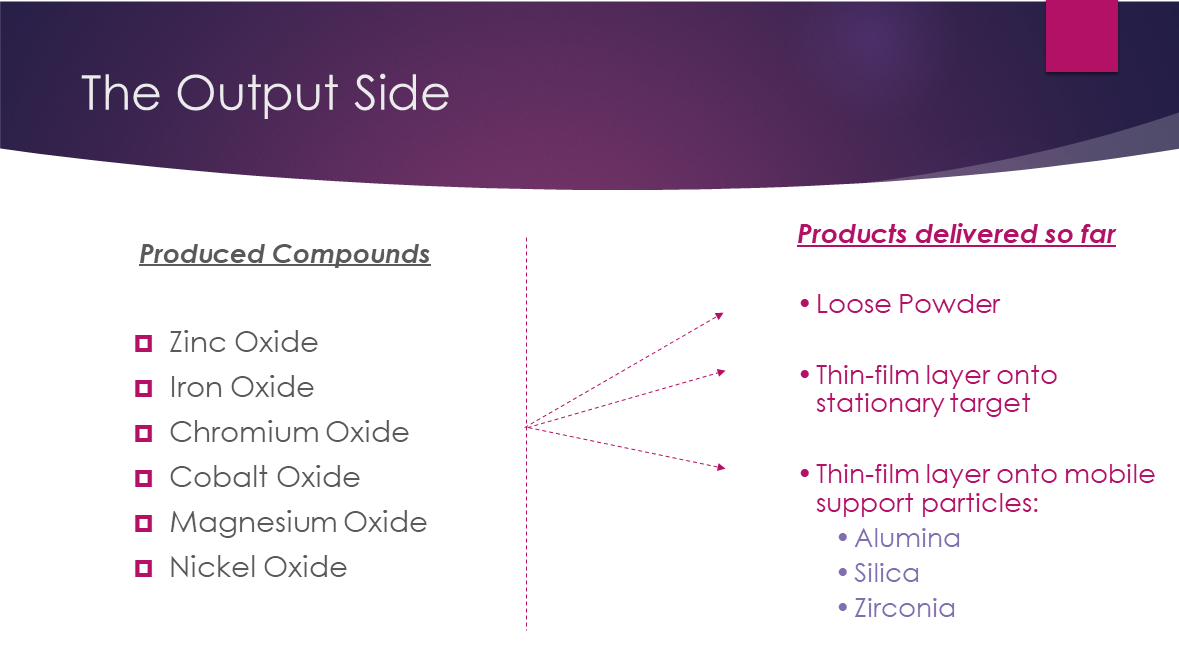

EDEN has exclusive global access to use a versatile patented Nano-Fabrication technology, PAN-FSP (Pulse-Assisted Nozzle using Flame Spray Pyrolysis), which offers unique benefits in manufacturing bulk nanopowders and complex high value nanostructured compounds. Importantly, it facilitates reliable cost-effective commercial-scale production of Advanced NanoTech Materials in a variety of forms, including: Bulk Nanopowders; Single/Multilayer Functional Nano-Coatings onto Flat or Curved Surfaces; and Single/Multilayer Functional Nano-Coatings onto Mobile Support Particles (such as Alumina, Silica, Zirconia Substrates from 1micron to 10mm diameter, with the nanostructured functional layer from 20nm to 10 micron thick, yielding an effective surface area magnification of 10 to 1,000 times, and more). EDEN's application of PAN-FSP utilizes liquid precursors as starting materials and incorporates a 'Programmable PAN-FSP Production Process' that enables reliable fabrication and commercial-scale production of many simple and complex nanostructured compounds AS WELL AS high value nanostructured materials with diverse form, shape, size, and structure morphology ranging in size (from 2nm to 2microns) and shape (from perfect spheres to hollow bird nest type structures, snowflakes, needle forms, and so on.

The EDEN Melbourne Nano-Fabrication Facility

The EDEN Australian NanoTech Centre in Melbourne is the first Advanced Nano-Fabrication Facility in the world to innovatively apply this streamlined manufacturing process to develop and produce (on a commercial scale) a wide range of "programmable" bulk nanopowders and advanced high value nanomaterials of consistently high quality (from course-grade down to very-fine-grade), with huge savings in resource needs, production time, energy usage, and cost. The facility has several production 'rigs' that can produce bulk nanopowders and (through suitable reconfiguration) complex nanomaterials at rates from 10 to 100 kg daily. For large-scale high-quality bulk nanopowders involving the simplest reaction of an aqueous solution of a metal nitrate to its corresponding nano-metal oxide, more than 50 types of pure metal oxide can be produced, ranging from Al2O3 through to ZrO2 (alphabetically). Flexibility also exists to create a myriad of mixed and complex nanostructured compounds. Importantly, the cost of Nano-Fabrication using PAN-FSP is very low due to its programmable feature and its streamlined production process for all types of high volume nanopowders and complex nanostructured materials.

Benefits of the EDEN Nano-Fabrication Process

- A low-cost nano-fabrication process that is programmable, scalable and versatile, with reliable simple operation and low maintenance.

- The only commercial-scale process for fabricating a wide range of nanomaterials with programmable form, shape, and size (down to 2nm).

- Operates as a One-Step process versus other methods requiring 6-12 separate processes.

- Enables ultra-fast deposition at 10-30 sec/layer versus 8-10 hours for PECVD (Plasma-Enhanced Chemical Vapour Deposition) and the like.

- Deposition is possible at Standard Environment Conditions, obviating the need for "normal" deposition cleanroom and vacuum facilities.

Courtesy of EDEN NanoTech Support